With a well-thought-out stocking of components Beckhoff can guarantee long-term availability throughout the product portfolio: The spectrum of options is exceptionally broad and ranges from company logos or special labels and individualized functions to Industrial PCs built in total accordance with the customer’s corporate design.

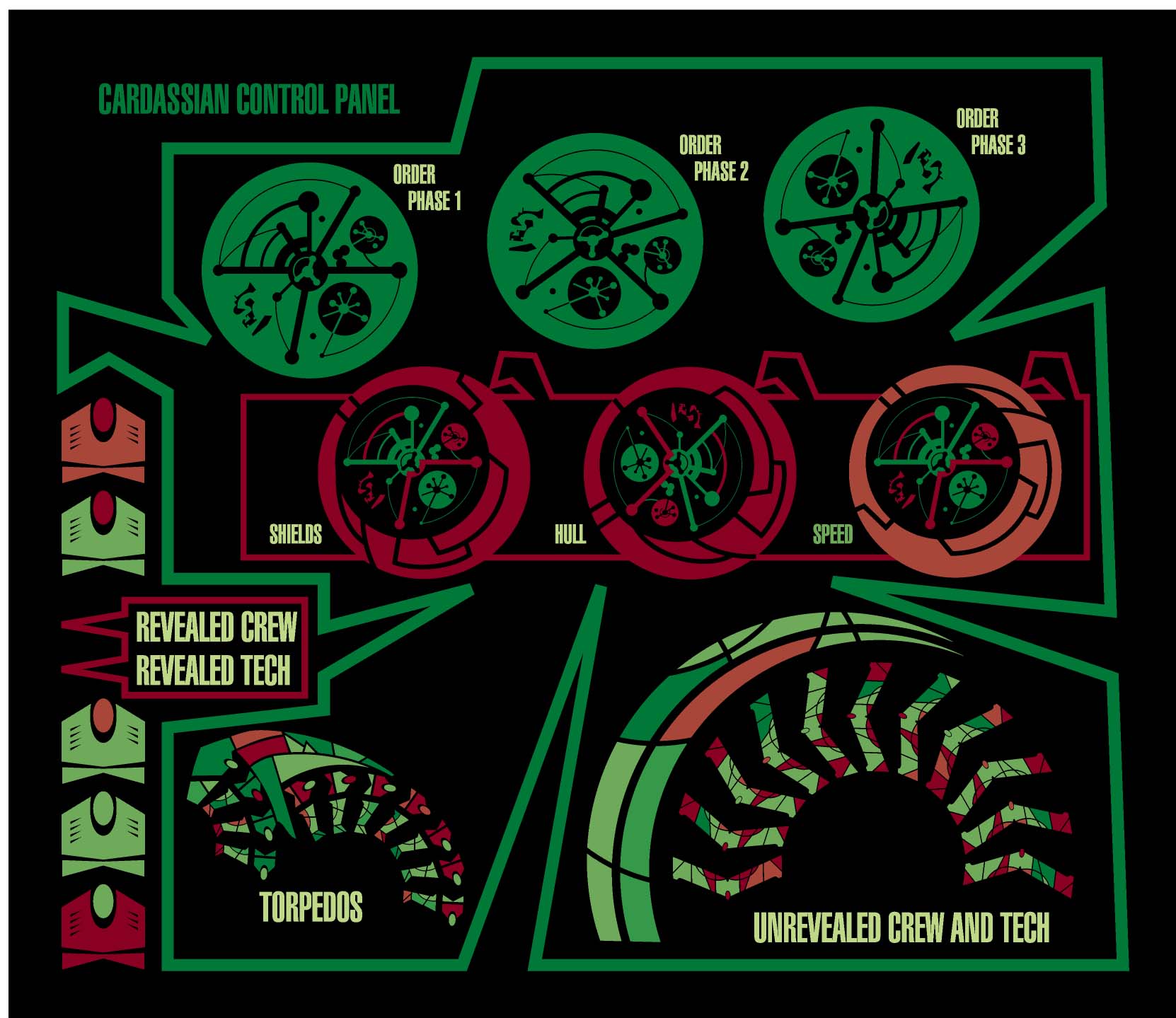

SPACESHIP CONTROL PANEL DESKTOP SOFTWARE

customized models in terms of mechanics, electrical and electronic components, software and design.wide range of interfaces and screen sizes for all protection classes and installation requirements.storage media flexibility: HDD, SSD, CFast, μSD.

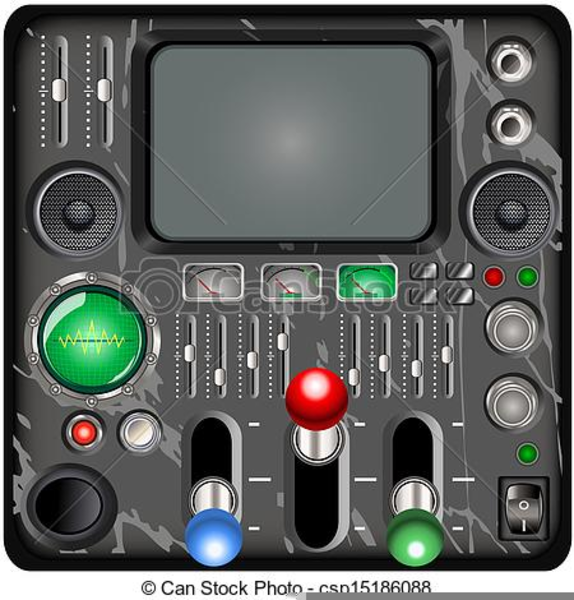

SPACESHIP CONTROL PANEL DESKTOP PC

With processors ranging from Intel ® Celeron ® to Core™ i7, different RAM and storage options, various operating systems and TwinCAT generations – the menu of options is vast, resulting in an almost unlimited variety of standard Industrial PC models: The product finder can help you select the desired configuration. Their flexibility in configuration allows users to choose exactly the devices that are best-suited to their specific applications. Standard Industrial PCs with variable configurationĪlmost no applications are exactly alike, and neither are most of the standard Industrial PCs from Beckhoff.

Beckhoff offers a highly scalable portfolio of Industrial PCs ranging from single-core to multi-core and many-core with all types of interfaces, display sizes, form factors with different or identical CPUs, and various protection classes. Select the Beckhoff Industrial PC that perfectly matches the job. In combination with the TwinCAT automation software, they offer a high-performance control system for PLC, NC and CNC functionalities.Īn important feature of the Beckhoff product philosophy is the use of latest, high-performance components and processors for the development and design of Industrial PCs: they integrate the latest developments offered by the technology market and are used successfully worldwide.

Beckhoff Industrial PCs are characterized by a wealth of technology know-how accumulated over recent years. For classic control tasks, PC-based control technology offers excellent scalability and flexibility and is therefore increasingly used in place of hardware PLCs.īeckhoff is one of the pioneers of PC-based automation: the first PC control system was delivered as early as 1986. Together with associated software, PCs in different shapes and forms are at the core of a wide range of diverse automation tasks such as control of machines, processes or logistics systems, networking of system components, data acquisition, or image processing. The personal computer has experienced an unprecedented success story and has become a firmly established part of everyday life, including industrial environments.

0 kommentar(er)

0 kommentar(er)